Aluminum Window Systems

Aluminum window systems consist of aluminum frames (the frame form of aluminum profiles), glass, and accessories such as window handles, railing hinges, and gaskets. Aluminum materials used in window systems stand out with their insulation properties, ability to support heavy glass, and ease of cleaning.

As for disadvantages, their unit weight is slightly higher than PVC window systems due to the weight of aluminum profiles, and their unit cost is relatively higher than plastic profiles. For this reason, they are especially preferred in large glass and commercial building applications. Additionally, since aluminum is a metal with high conductivity, insulation in aluminum windows is generally achieved by incorporating extra thermal insulation plastics within the aluminum frames.

Aluminum window models offer a wide range of variety, including sliding systems, double-opening systems, tilt-and-turn systems that open as much as the attached hinges allow, and folding systems. Additionally, aluminum windows are available in their unique standard gray (anodized) color, as well as many other color options.

Aluminum window systems go through three main stages before being ready for installation. In the first stage, aluminum profiles are produced using the extrusion method in the factories of major manufacturers. In the second stage, companies like ours, specializing in ready-to-use aluminum window manufacturing, process these profiles through cutting, milling, and corner crimping to form frames. In the third stage, the frames are integrated with the glass to complete the aluminum window assembly.

When calculating prices, glass is typically measured in square meters, while aluminum frames are measured in linear meters to determine the total cost.

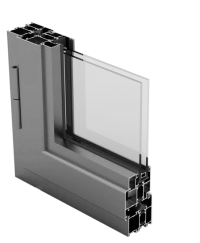

Aluminum Window Systems Details and Technical Specifications

Frame Depth: 45.5 mm

Wing Depth: 45.5 mm

Profile Wall Thickness: 1.1 – 1.2 – 1.4 – 1.5 – 2 mm

Glass Thickness: 4 mm – 26 mm

For application options and all profile details, download the catalog from here .

Frame Width: 55 – 64.5 mm

Wing Width: 63.5 – 73 mm

Thermal Barrier: 15 mm

Profile Wall Thickness: 1.3 – 2 mm

Glass Thickness: 4 mm – 36 mm

Min. Wing Dimensions: 350 x 500 mm

Max. Wing Dimensions: 1300 x 2800 mm

Max. Wing Weight: 130 kg

EN 12152 Air Permeability: Class 3 (600 Pa)

EN 12154 Water Permeability: Class 9A (600 Pa)

EN 13830 Wind Resistance: Class C3 (1200 Pa)

Min. Thermal Insulation: Uw: 2.7 – 3.7 W/(m2.K)

For application options and all profile details, download the catalog from here.

Frame Width: 70 – 80.5 mm

Wing Width: 77.5 mm

Thermal Barrier: 24 mm

Profile Wall Thickness: 1.5 – 2 mm

Glass Thickness: 16 mm – 45 mm

Min. Wing Dimensions: 350 x 700 mm

Max. Wing Dimensions: 1300 x 2800 mm

Max. Wing Weight: 130 kg

EN 12152 Air Permeability: Class 3 (600 Pa)

EN 12154 Water Permeability: Class 9A (600 Pa)

EN 13830 Wind Resistance: Class C3 (1200 Pa)

Min. Thermal Insulation: Uf: 1.8 – 2.1 W/(m2.K)

For application options and all profile details, download the catalog from here.