What is Structural Silicone Curtain Wall (Cassette System)?

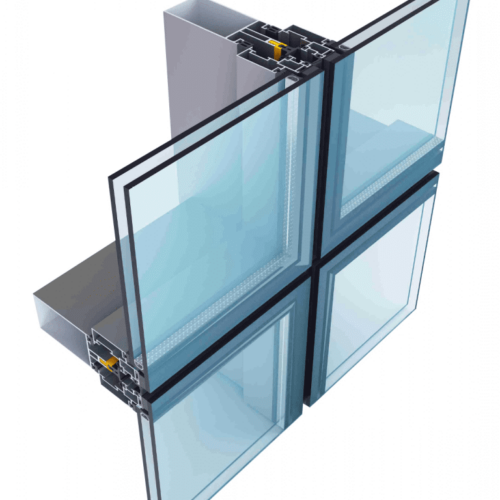

Structural silicone curtain wall is a façade cladding system commonly used in modern buildings. This system is formed by bonding the glass to aluminum cassette profiles with structural silicone and then screwing them onto aluminum supports. Since only silicone is visible between the glass panels, the façade surface is smooth, and the outlines of the cassette profiles behind the glass can be seen.

Strüktürel silikon giydirme cephe sistemleri, modern mimari tasarımlarda yaygın olarak kullanılan, estetik ve fonksiyonel avantajlara sahip olan özel bir cephe kaplama sistemidir. Bu sistemlerin öne çıkan özellikleri şunlardır.

- Visible Lines: From the outside, there’s a black frame-like appearance behind the glass mounted onto cassette profiles with structural silicone. However, since there are no metal frames between or on top of the glass panels, it offers a seamless and clean aesthetic. This lends a modern and elegant look to buildings.

- High Adhesion Strength: The structural silicone used strongly bonds the glass to the metal cassette profiles. This ensures façade stability against high wind loads, earthquakes, and other external factors.

- Energy Efficiency: When paired with energy-efficient glass options such as laminated or low-e glass, structural silicone curtain walls provide energy savings through insulation and solar control.

- Acoustic Insulation: Combined with soundproofing glass, these façades can deliver excellent acoustic isolation, especially in areas with heavy traffic.

- Corrosion Resistance: Aluminum cassette profiles and support systems have high resistance to corrosion, ensuring long-term durability.

- UV Resistance: Structural silicones are resistant to UV rays, preventing yellowing or deterioration over time.

- Flexible Design: This system provides architects and designers with broad creative freedom. Personalized designs can be achieved with various glass sizes, shapes, and colors.

- Safety: Using laminated or tempered glass can enhance the safety standards of structural silicone curtain walls.

- Easy Maintenance: Maintenance is relatively easier since the absence of metal frames eliminates obstacles during cleaning.

- Air and Water Tightness: These systems deliver high performance in air and water tightness with proper installation and engineering.

These features highlight the numerous aesthetic and functional advantages of structural silicone curtain wall systems. However, such systems require professional expertise for installation and maintenance, and regular inspections are essential. Additionally, compared to traditional capped curtain walls, they are easier to install but are more expensive due to the specialized structural silicone required. While more costly than frameless silicone wall systems, their installation is comparatively easier.

Cassette Structural Silicone Wall Components

The structural silicone wall system comprises numerous elements forming a complex structure. These components are crucial for the system’s functionality, aesthetics, and performance. Here are the primary components of a structural silicone facade system.

Structural Silicone Curtain Wall Components

Structural silicone façade application requires expertise and experience. Every step performed during installation must be completed carefully and accurately to ensure the façade’s longevity, durability, and functionality. Therefore, it is recommended that such installations are carried out by a skilled and trained team. For technical support regarding structural silicone façade installation, please contact us.

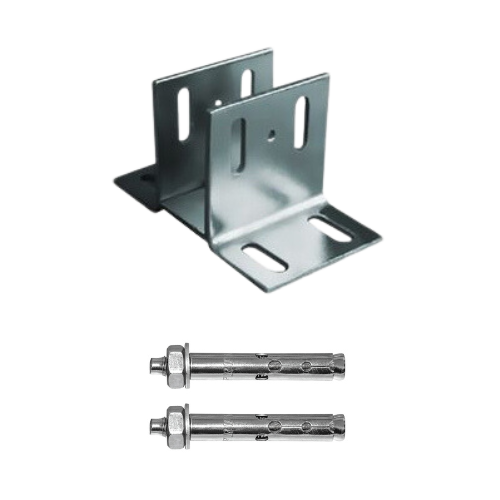

These components ensure that the structural silicone façade system is securely mounted to the main structural frame of the building. Steel anchors and anchor connections guarantee a strong and safe attachment of the supporting systems to the building.

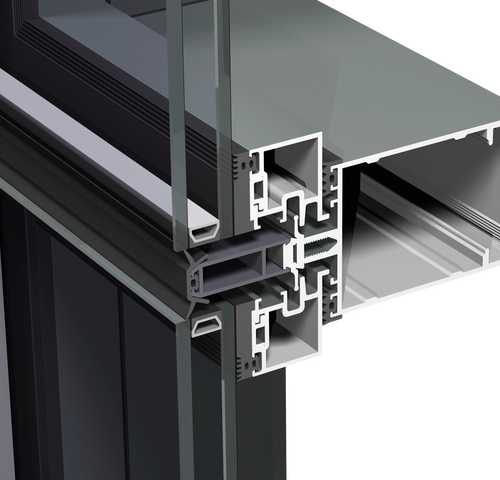

These profiles, made of aluminum or other metals, are the main skeleton system that carries and supports the glasses. Aluminum is generally used because it is a light, durable and corrosion-resistant material.

These elements ensure that structural silicone facade systems are airtight and waterproof. They also maintain structural integrity by acting as a buffer between system elements during thermal expansion and contraction.

These profiles are mounted behind the glass and connect the glass to the carrier frame. The glass is bonded to these profiles with structural silicone adhesive.

Various types of glass (tempered, laminated, low-e etc.) can be used in structural silicone facades. The type of glass selected determines the energy efficiency, solar control, acoustic insulation and security features of the facade.

This special adhesive ensures strong and durable adhesion of glass to cassette profiles. Structural silicone has high resistance to UV rays, weather conditions and aging.

Some structural silicone facades may have opening wings for functional needs such as ventilation or emergency exits. These wings allow a certain area on the facade to be opened without compromising the aesthetic integrity.

When all of these elements come together, a facade system that is both aesthetically and functionally superior is created.

Structural Silicone Curtain Wall Technical Specifications

- Profile Width: 50mm

- Profile Wall Thickness: 1.4 – 2.5 mm

- Vertical Mullion Depth: 50 – 180 mm

- Horizontal Mullion Depth: 30 – 126 mm

- Minimum Glass Thickness: 4 mm

- Maximum Glass Thickness: 45 mm

- Minimum Sash Size: 700 x 1200 mm

- Maximum Sash Size: 1500 x 2000 mm

- Maximum Sash Weight: 155 kg

- EN 12152 Air Permeability: A4 – 600 Pa

- EN 12154 Water Tightness: RE 1200 Pa

- EN 13830 Wind Load Resistance: 1200 Pa

- Minimum Thermal Insulation (Uf): 2.64 – 3.88 W/(m²·K)

What Are the Glass Features of Structural Silicone Curtain Wall Systems?

This section describes the characteristics of the glass used in structural silicone curtain wall systems. Such glass is typically high-performance and specialized to meet the demands of energy efficiency, aesthetics, safety, and other critical considerations for the facade. The outlined features highlight the specific capabilities and advantages that these glass types bring to silicone curtain wall applications.

What Are the Colors of Structural Silicone Curtain Wall Glass?

Silicone curtain wall glass is generally manufactured in a variety of colors and coatings to meet both aesthetic and functional requirements. These coatings and colors can affect energy efficiency, solar control, and aesthetics. Here are the common color and coating options for silicone curtain wall glass.

Structural Silicone Curtain Wall Glass Colors

Low-e Coatings: These coatings optimize the heat and light transmission properties of the glass. They create a barrier against ultraviolet and infrared rays, preventing excessive indoor heat and reducing heat loss.

Solar Control Coatings: These coatings help reduce excessive heat from sunlight and also provide protection against UV rays.

Tinted Glass: Glass produced in different colors offers aesthetic variety and absorbs some sunlight, preventing excessive indoor heat buildup. Common tints include bronze, gray, green, and blue.

Reflective Coatings (Reflective Glass): Reflective glass coatings reflect a portion of incoming light, helping to maintain indoor temperature control. They also provide an aesthetic sheen and a mirror-like effect.

Frosted Glass: This type of glass has a textured or acid-etched surface. It limits visibility, enhances privacy, and adds an aesthetic touch.

Digitally Printed Glass: With digital printing technology, graphics, patterns, or images can be directly applied to the glass surface. This allows for customized aesthetic options.

How to Install a Structural Silicone Curtain Wall?

The production of these facades involves not only aesthetics but also engineering excellence. The process, from cutting the aluminum mullions and cassette profiles to attaching the glass to these profiles, requires meticulous planning, precise execution, and continuous quality control. Here are the main steps in the production of a structural silicone curtain wall.

Structural Silicone Curtain Wall Production

- Initially, aluminum profiles and glass of the appropriate thickness and specifications are selected according to the project’s requirements.

- The glass is cut to the specified dimensions.

- Its edges are sanded and cleaned. This ensures better adhesion of the silicone adhesive.

- If necessary, coatings or other treatments are applied to the glass surface.

- Throughout the entire manufacturing process, critical parameters such as cutting accuracy, the quality of silicone application, and overall joint strength are regularly monitored.

These processes are crucial for creating a structurally sound, durable, and aesthetically pleasing silicone facade system. Expertise and experience in structural silicone facade manufacturing are essential to ensure the proper integration of glass and aluminum profiles. For assistance with silicone facade manufacturing, contact us here.

How is Structural Silicone Curtain Wall Installation Done?

The installation of these facades is a process that requires precision, care, and expertise. Here are the basic stages of structural silicone facade installation.

Structural Silicone Facade Installation

- Safety measures are taken at the construction site. The work area is cleaned, and the necessary equipment is prepared for installation.

- Anchors and connection elements that will attach the facade to the main structural components are installed.

- Pre-fabricated aluminum grillages are mounted onto walls or supporting elements using steel anchors or other suitable fasteners.

- These grillages serve as the primary structural system that will support and transfer the weight of the glass panels to the building’s framework.

- Fabricated glass panels, pre-attached with cassette profiles, are prepared for installation onto the aluminum grillage system.

- These panels are mounted to the grillage system using appropriate fasteners (typically screws). During this process, structural silicone is applied to both faces of the panel to provide adhesion and waterproofing.

- The silicone is carefully applied to ensure even and secure bonding between the glass and the cassette profile.

- The gaps between glass panels are sealed with gaskets and seals to ensure airtightness and waterproofing.

- These seals enhance the overall water resistance and provide thermal insulation for the façade.

- If the design includes operable windows or ventilation elements, these components are also mounted onto the grid system.

- Once installation is complete, the entire façade is tested for water tightness, air permeability, and structural durability.

- Any deficiencies or issues identified are corrected as needed.

What are the costs of structural silicone curtain wall systems?

The cost of silicone facades can vary depending on many different factors. Below is a guide to the main factors that affect the cost and general information on this subject.

Structural Silicone Curtain Wall Cost

- Material Costs:

- Glass: The type of glass used (tempered, laminated, low-e, reflective, etc.), its thickness, and coatings determine its per square meter price.

- Aluminum Profiles: The quality, cross-section, and surface treatment (anodizing, painting, etc.) of the profile affect the cost.

- Silicone and Other Materials: The quality and type of structural silicone, as well as gaskets, seals, and other auxiliary materials, make up the cost. This is a particularly significant factor when compared to traditional capped curtain wall systems.

- Manufacturing and Labor Costs: Labor costs vary depending on the complexity of the installation and manufacturing, as well as the size and requirements of the project.

- Design and Engineering Costs: For projects requiring custom designs or engineering solutions, these services add to the total cost.

- Transportation and Logistics: Depending on the project’s location, material transportation and logistics costs must be factored in.

- Additional Costs: Specific projects may require special tests, certifications, or other additional services, which can increase the overall cost.

- Regional Factors: Local economic conditions, competition levels, supply-demand balances, and other regional factors influence pricing.

When estimating costs, it is essential to develop a detailed budget based on the specific needs and requirements of a project. Contacting local suppliers, manufacturers or experts is the best way to get the most accurate and up-to-date pricing information. However, in all cases, careful planning and research should be done to minimize costs without compromising quality.

Structural Silicone Curtain Wall Prices

Pricing for structural silicone curtain walls is typically given per square meter and can vary significantly depending on numerous factors. These include the quality of the materials used, the complexity of the project, design features, regional cost variations, and many other parameters.

On average, the cost for structural silicone curtain walls ranges from $150 to $250 per square meter. However, this is a general estimate, and prices may fall outside this range depending on the specific requirements and characteristics of a given project.

Structural Silicone Curtain Wall Companies

Structural silicone facade applications are frequently preferred in modern architectural building exteriors, with numerous specialized companies operating in this field. Firms that focus on structural silicone facades typically excel in architectural glass applications, aluminum profile production, and installation services.

Üçgen Alüminyum is one of the prominent companies in the structural silicone facade sector. Some of the company’s key features include:

- Triangular Aluminum:

- Expertise Areas: Triangular Aluminum is a company that specializes not only in silicone facade applications but also in various aluminum systems.

- Quality Assurance: The company adheres to quality standards and prioritizes customer satisfaction as a core principle.

- Innovation: By closely following modern architectural trends and technological advancements, it offers innovative solutions.

- Project-Based Solutions: Recognizing that each project has unique requirements, Triangular Aluminum provides customized solutions to meet those needs.

Other companies engaged in silicone facade applications operate in the sector with various areas of expertise, quality standards, and service networks. However, companies like Triangular Aluminum, well-known and preferred in the industry, stand out for their experience and the quality of services they offer. If you are planning to implement a silicone facade application for a project, it’s important to review the company’s previous projects, check their references, and get in touch for a detailed proposal.