What Are Capsulated Curtain Wall Systems?

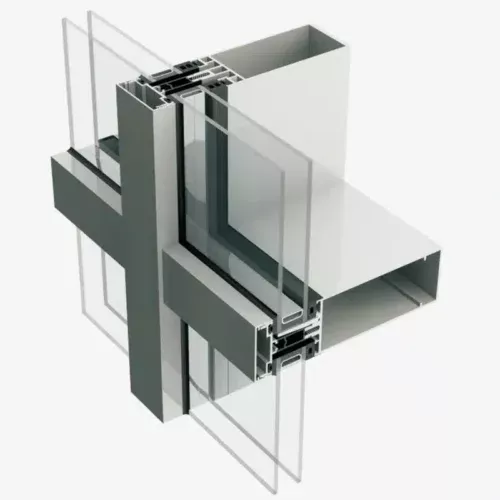

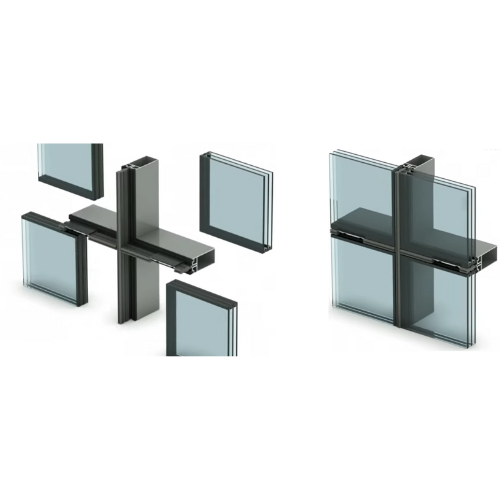

Capsulated curtain wall systems represent an innovative exterior cladding solution, commonly chosen for contemporary building designs. This approach involves fastening glass panels to aluminum carrier profiles using pressure profiles and screws, resulting in a structure where the aluminum frames remain visible from the outside. By combining aesthetics and functionality, capsulated glass curtain walls lend a sleek, modern appearance to buildings.

In aluminum capsulated curtain wall systems, the edges of glass panels are surrounded by aluminum caps. These caps not only serve as an aesthetic frame but also cover the pressure profiles that securely attach the glass panels to the supporting structure.

What are the features of capsulated curtain walls?

Capsulated curtain wall systems are a frequently chosen facade cladding solution in modern architecture. In addition to aesthetic appeal, they offer a range of functional benefits. Here are the standout features of capsulated curtain wall systems.

Capsulated Curtain Wall Features

- Aesthetic Appeal: Capsulated glass curtain walls give buildings a sleek, modern appearance. The aluminum frames elegantly surround the glass panels, creating visual harmony.

- High Light Transmission: These systems allow abundant natural light to enter the structure, making interior spaces brighter and more inviting.

- Energy Efficiency: Capsulated glass curtain walls can be paired with energy-efficient glass options such as double glazing or low-emissivity (Low-E) glass. This integration helps reduce heating and cooling costs.

- Durability: The natural strength of aluminum ensures that capsulated curtain wall systems are long-lasting. Corrosion-resistant materials provide superior protection against environmental factors.

- Air and Water Tightness: High-quality gaskets and seals achieve excellent air and water tightness, helping the system withstand extreme weather conditions.

- Ease of Maintenance and Cleaning: Capsulated curtain wall systems are easy to clean due to their smooth surfaces. The aluminum frames are made from robust materials that require minimal maintenance.

- Safety and Security: Laminated or tempered glass options provide enhanced safety and security. Even if broken, the glass is designed to reduce the risk of injury.

- Flexible Design Options: Capsulated curtain walls can be customized with aluminum frames in different colors and finishes, offering flexible design possibilities to meet project aesthetics.

- Incorporation of Operable Panels: Operable panels can be integrated into capsulated curtain wall systems for ventilation or emergency egress purposes.

These features make capsulated curtain wall systems an ideal exterior cladding solution for modern buildings, combining aesthetics and functionality.

What are the Models of Capsulated Curtain Walls?

Covered curtain wall systems offer an important solution that combines flexibility and aesthetic appeal in modern architectural designs. The use of cover profiles allows designers and architects to personalize the external appearance of buildings by offering various aesthetic options. Here are the covered curtain wall models and the design flexibility these models provide.

Capsulated Facade Models

Standard Capsulated Curtain Wall: Aluminum cap profiles are placed both vertically and horizontally, giving the facade a grid-like appearance. This standard application not only provides the facade with a serious, modern look but also ensures reliability in terms of structural strength.

Semi-Capped Curtain Wall: In this model, caps are applied only vertically or horizontally, creating an uninterrupted appearance along a single axis between the glass surfaces. The semi-capped curtain wall provides a modern and minimalist aesthetic, while maximizing the amount of natural light entering the building.

Almond-Capped Facade: When cap profiles are designed in an almond shape, they impart a unique and dynamic appearance to the facade. In addition to adding aesthetic character to the building, almond-capped facades may also provide functional benefits such as solar control and shading.

Specially Shaped Capped Facade: Caps applied in H shapes, diagonal patterns, or other unique geometric designs give buildings a distinctive identity. Specially shaped capped curtain walls provide ample opportunity to bring creative design concepts to life. These caps add depth and visual interest to the facade while enhancing shading and aesthetic cohesion.

Thanks to the use of cover profiles, covered glass curtain wall systems can be diversified in accordance with the architectural language and aesthetic preferences of the project. This flexibility allows the creation of visually appealing facades that are in harmony with the surroundings of the buildings. Each model can be designed to meet a specific aesthetic expression or functional requirement, thus strengthening the identity of the buildings and contributing to the integrity of the architectural design.

What Are the Components of Capped Facades?

Capped curtain wall systems are created by combining a range of specialized components that provide both aesthetic and functional benefits. These key elements support the structure both visually and structurally. Below are the main components of capped curtain wall systems.

Capped Curtain Wall Components

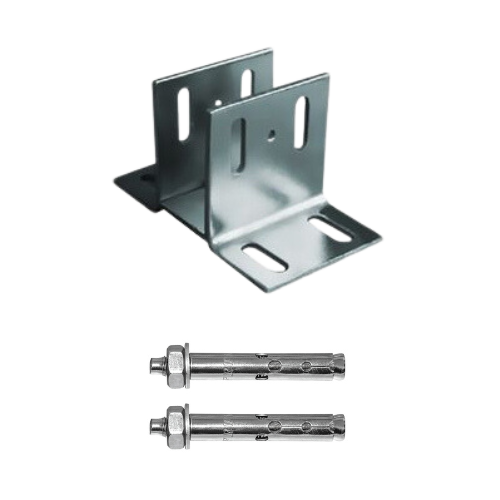

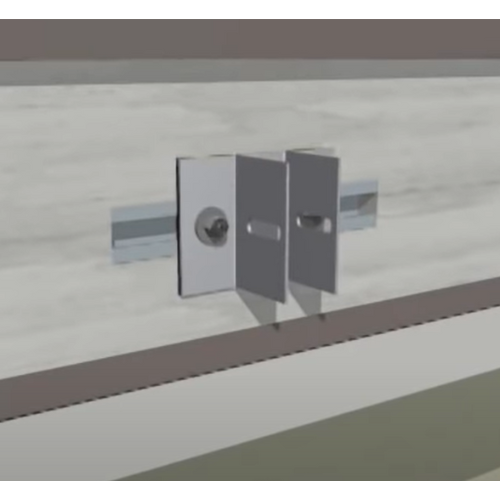

These are the elements that ensure the safe connection of aluminum carrier profiles to the main carrier structure of the building. These connections are of critical importance for the system to be firmly fixed to the structure.

These profiles form the main skeleton of the system and provide the necessary support and stability for the assembly of glass panels. These profiles also increase structural integrity and durability.

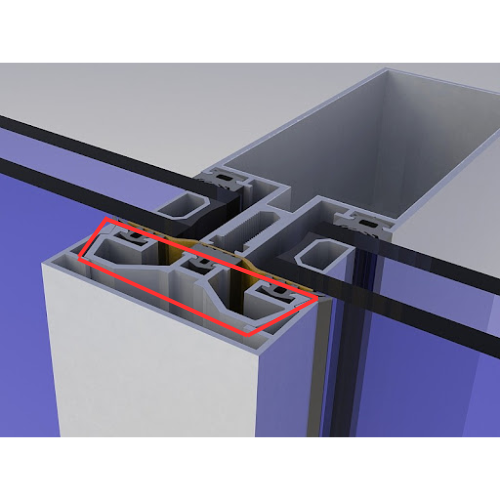

It is applied on and between the facade profiles and the areas in contact with the glass, and provides sealing and insulation.

They are the main elements that provide the aesthetic appearance of the facade, allow natural light to enter and establish a visual connection between the exterior and interior. Glass can be used in various types and coatings.

These are profiles that are applied with pressure and are used to connect glass panels to aluminum carrier profiles. These profiles ensure that the glass remains fixed in place and contribute to structural integrity.

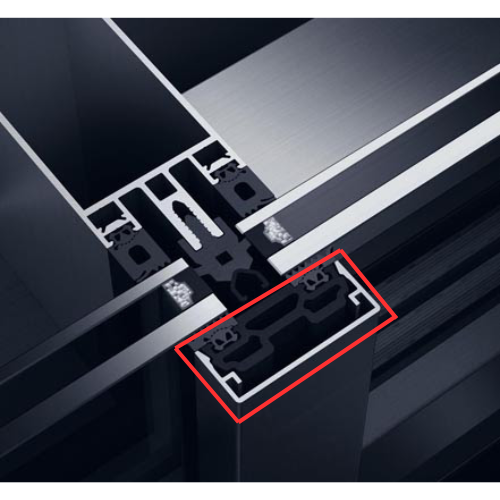

They are aluminum profiles used to provide an aesthetic appearance and to cover the connection points of the press profiles and glass panels in an aesthetic way. Cover profiles give the facade a smooth and finished appearance.

It is filled under the press profile and between the glass panels to ensure air and water tightness. Silicone is used to seal the joints between the glass panels and to provide extra adhesiveness.

An opening wing can be integrated into the façade, opening inwards or outwards, which does not disrupt the integrity when viewed from the outside and allows ventilation of the interior.

Capped Curtain Wall Technical Specifications

- Profile Width: 50mm

- Profile Wall Thickness: 1.4 – 2.5 mm

- Vertical Mullion Depth: 50 – 180 mm

- Horizontal Transom Depth: 30 – 126 mm

- Minimum Glass Thickness: 4 mm

- Maximum Glass Thickness: 45 mm

- Minimum Sash Size: 700 x 1200 mm

- Maximum Sash Size: 1500 x 2000 mm

- Maximum Sash Weight: 155 kg

- EN 12152 Air Permeability: A4 – 600 Pa

- EN 12154 Watertightness: RE 1200 Pa

- EN 13830 Wind Load Resistance: 1200 Pa

- Minimum Thermal Insulation: Uf: 2.64 W/(m^2.K)

What Are the Characteristics of Clad Glass Facades?

Characteristics of Clad Glass Facade

How Are the Dimensions of Framed Facade Glass?

The glass used in covered curtain wall systems can be designed in different sizes, taking into account structural requirements, aesthetic expectations and functional needs. Here are some details about the typical sizes of covered facade glass.

Framed Curtain Wall Glass Dimensions

| Feature | Value |

| Glass Thickness | 4 mm – 45 mm |

| Minimum Panel Dimensions | 700 mm x 1200 mm |

| Maximum Panel Dimensions | 1500 mm x 2000 mm |

| Maximum Panel Weight | 155 kg |

What Are the Colors of Framed Facade Glass?

The glass used in covered facade systems can have a wide range of colors. The color of the glass is usually obtained by adding metal oxides into the glass or by coatings applied to the glass surface. These colors can affect both the aesthetic appearance and the functional properties of the glass. Here are the colors frequently preferred in covered facade glass.

Framed Curtain Wall Glass Colors

- Clear / Natural: This is the most commonly used type of glass, offering maximum natural light transmission.

- Bronze: Absorbs a portion of sunlight, reducing heat load, and gives buildings a warm appearance.

- Gray: A neutral color that balances light transmission while providing solar control.

- Blue: Provides an aesthetically pleasing appearance that harmonizes with the sky, filtering sunlight to help keep indoor spaces cool.

- Green: Provides a natural look and reduces heat load by absorbing some of the sunlight.

- Reflective / Mirrored: Reflects sunlight and heat to keep interiors cool. Additionally, it creates a reflective surface from the outside, enhancing privacy.

- Opaque / Matte: Provides full or partial privacy while maintaining light transmittance.

These color options can be used in glass facade systems to give buildings a unique character and create a certain atmosphere. The color of the glass can also have a significant impact on the heat and light control within the building. Therefore, the selection of the glass color should be made carefully in accordance with the aesthetic and functional requirements of the project.

Capped Curtain Wall Details

How to Build a Capped Curtain Wall?

<p>The production of capped curtain wall systems requires a meticulous process to ensure both aesthetic and structural integrity. This process spans from design and engineering to material manufacturing and quality control. Here are the main steps involved in the production of capped curtain wall systems.</p>

Capped Curtain Wall Production

- The production of capped curtain wall systems begins with detailed design and engineering studies tailored to the unique requirements of the project. At this stage, factors such as the aesthetic appearance of the facade, structural durability, and energy efficiency are taken into account. The dimensions, shapes, and material properties of all components of the facade system (aluminum supporting profiles, glass panels, pressure plates, and cover caps) are determined.

- The aluminum supporting profiles are the main load-bearing elements of the facade system. They are cut, drilled, and shaped using CNC machines that require high precision. To provide corrosion protection and achieve a polished appearance, the profiles undergo surface treatments such as anodizing and powder coating.

- Glass panels are cut according to the specified dimensions and the necessary processes (tempering, lamination, coating, etc.) are applied. These processes increase the safety, energy efficiency and aesthetic properties of the glass. The edge processes of the glass panels are also done at this stage, so that a perfect fit is achieved during assembly.

- Press profiles are used to fix glass panels to aluminum carrier profiles and are manufactured with high precision. Cover profiles are designed and manufactured to give a finished appearance to the facade. These profiles are used to aesthetically frame the glass panels.

- Openable wings to be integrated into the covered facade are manufactured. While a cassette profile is not required behind the glass on the facade, it is required for the opening wing.

The manufacturing of covered curtain wall systems is characterized by the use of high-quality materials and detailed engineering studies. This process is of critical importance to ensure that the facade systems are long-lasting, aesthetic and functional. In addition, errors in manufacturing are kept to a minimum in order to avoid problems during the assembly stages.

How to Install a Capped Curtain Wall?

Capped Curtain Wall Installation

- The assembly process begins with the secure attachment of the aluminium carrier profiles to the main carrier structure of the building using anchors and dowels. This forms the foundation of the façade and provides structural strength.

- In order to ensure air and water tightness, special wicks and gaskets are placed on and between the aluminum profiles. This process increases the insulation performance of the facade.

- For fixing the glass panels in place and additional sealing, press profiles are installed and silicone sealant is applied to the required points.

- To provide an aesthetic finish, cover profiles are mounted on the pressure profiles around the glass panels. Cover profiles hide the pressure profiles and assembly details in an aesthetic way.

- Silicone is applied to the edges of the glass panels and the connection points of the cover profiles to provide extra water and air tightness.

- Following completion of the installation process, a comprehensive quality control process is carried out on the system. This is important to verify the accuracy of the installation, the tightness of the façade and its overall structural integrity.

Covered curtain wall installation is a process that requires meticulousness and expertise to create a high-performance exterior wall system, both aesthetically and functionally. Therefore, it is essential to use experienced professionals and the correct installation techniques for the installation process to be successful.

What are the Costs of Capped Curtain Walls?

The cost of capped curtain wall systems can vary greatly depending on a number of factors. These include the type and quality of materials used, the properties of the glass, the size and complexity of the facade, labor costs, the geographic location of the project, and any additional features or requirements. Below are some key factors affecting capped curtain wall costs and general information about those costs.

Capped Curtain Wall Costs

- Material Costs: The quality and characteristics of materials such as aluminum carrier profiles, capping profiles, and glass panels have a significant impact on total costs. For instance, high-energy-efficiency glass or specially coated glass may be more expensive.

- Design and Engineering: The more complex the façade design, the more engineering and design efforts are required, which can increase costs.

- Labor Costs: The complexity of the installation and the level of expertise required affect labor costs. Labor costs can also vary by geographic region.

- Additional Features and Functions: Extra features such as operable windows, special solar controls, or automated ventilation systems can increase project costs.

- Project Location: Material supply, transportation, and logistics costs vary depending on the project’s location. Additionally, local labor costs in a particular area can influence the overall cost.

Framed Curtain Wall Prices

Generally, the price of framed curtain wall systems ranges from 180 to 220 dollars per square meter. For more complex projects requiring specialized materials, the cost may be significantly higher. Therefore, it’s essential to obtain detailed quotes from local suppliers or curtain wall system experts based on the full project specifications.