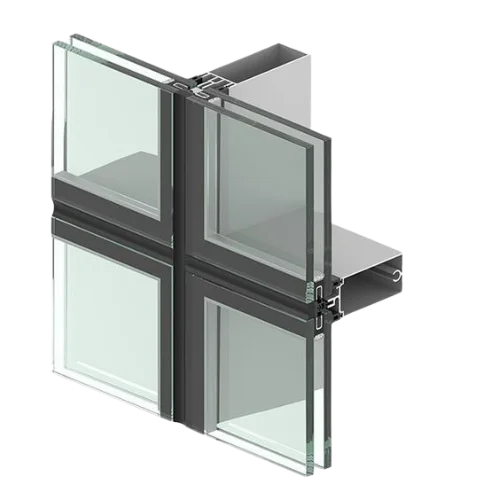

What is a Silicone Facade (Without Cassettes)?

Silicone facade (cassette-free) systems are a modern, aesthetic, and functional exterior cladding solution favored by contemporary architecture. These systems use specialized clips that screw into unique profiles on the edges of the glass panels to securely attach them to the aluminum silicone facade structure. Compared to cassette-based systems (structural silicone facades), cassette-free silicone facade systems offer a more cost-effective alternative since they do not require cassette profiles. However, they may take longer to install than cassette-based systems.

What are the Features of Silicone Facade?

Silicone facade systems are an innovative exterior solution preferred in terms of aesthetics and functionality, especially in modern architectural projects. The basic features of silicone facade systems are as follows.

Silicone Facade Features:

- Visual Appeal: Silicone façade systems offer a modern and transparent appearance by minimizing visible frames and maximizing glass surfaces. These systems provide seamless indoor-outdoor transitions, making the most of natural light.

- Energy Efficiency: With high-performance glass and effective sealing properties, silicone façade systems deliver excellent thermal insulation. This reduces energy consumption within the building and boosts overall energy efficiency.

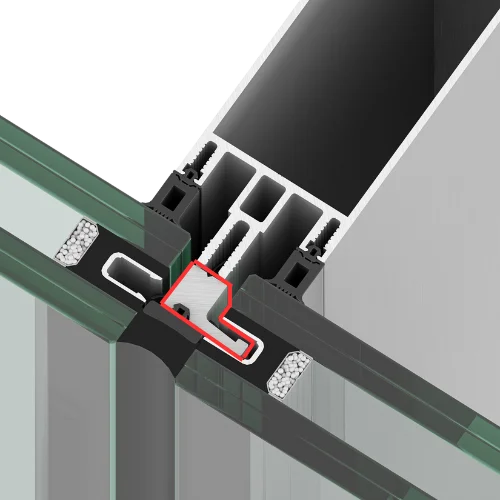

- Durability and Installation Method: Glass panels are secured to the structural aluminum frame using interstitial profiles and specialized clips. This unique connection method ensures high durability against wind loads, temperature fluctuations, and other external factors. Clips help firmly anchor the glass panels, maintaining structural integrity.

- Water and Air Tightness: Silicone façade systems are designed to be highly resistant to water and air penetration. This enhances interior comfort and helps preserve structural integrity over time.

- Longevity: The silicone material used has high UV resistance, preventing yellowing over time and maintaining its performance. This ensures the façade retains both its aesthetic and functional qualities for an extended period.

- Flexible Design Options: Silicone façade systems are compatible with various glass types, colors, and coatings. This gives architects and designers the freedom to create unique and innovative exterior designs.

- Easy Maintenance: The smooth and uninterrupted surfaces of silicone façade systems make cleaning and maintenance straightforward.

What are Silicone Facade Elements?

Silicone facade systems are an aesthetic and functional exterior solution that covers the exterior surfaces of modern buildings. These systems are created by combining a series of specialized elements. Here are the basic elements of silicone facade systems.

Silicone Facade Elements:

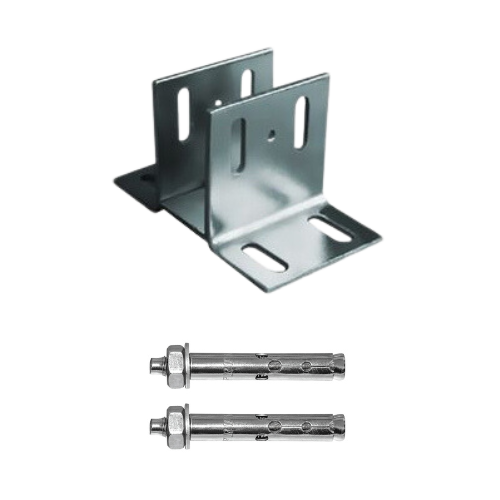

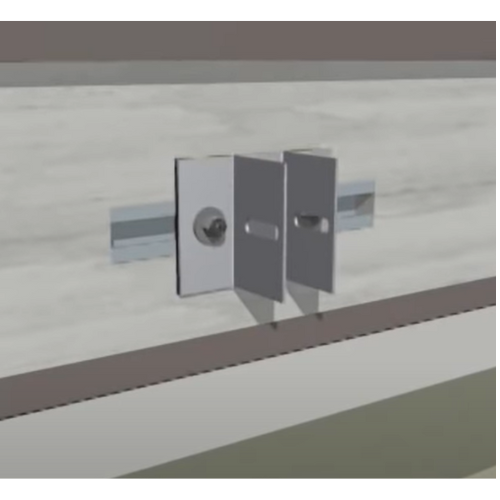

It ensures that the aluminum silicone facade profiles are securely connected to the main carrier system of the structure. These connections are critical for the system to be firmly fixed to the structure.

Profiles made of aluminum form the skeleton of the silicone facade system. These profiles are designed for the assembly and support of glass panels.

Used to ensure air and water tightness. These elements are located around the glass panels and at the assembly points, increasing the resistance of the facade to air and water.

These strips, used on the edges of glass panels, play a key role in the assembly of glass to aluminum profiles and carrier systems. These strips are specially designed to maintain the integrity of the glass and the structure.

They provide the connection of glass panels to the frame made of aluminum profiles. They screw the aluminum carrier profile to the slats located on the edges of the glass.

Tempered or laminated glass is usually used. These glasses not only provide the aesthetic appearance of the facade, but also have functional properties such as heat and sound insulation.

It is filled between the glass panels and serves to both provide sealing and create a smooth surface when viewed from the outside.

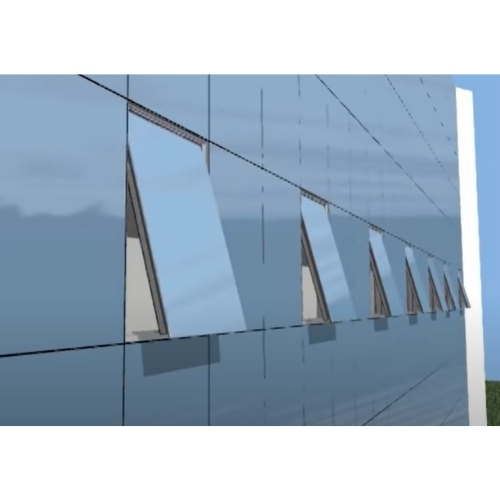

They are openable window or door elements designed for ventilation or emergency exit needs. These wings meet functional needs while maintaining aesthetic integrity.

When combined, these elements of silicone facade systems create a modern and durable exterior solution. These systems simultaneously offer aesthetic appeal, energy efficiency, and structural integrity. The installation process requires careful and precise assembly of these specialized components, making professional installation and application crucial.

Silicone Facade Technical Specifications

- Profile Width: 50mm

- Profile Wall Thickness: 1.6 – 2.0 mm

- Vertical Mullion Depth: 60 – 150 mm

- Horizontal Transom Depth: 60 – 150 mm

- Minimum Glass Thickness: 20 mm

- Maximum Glass Thickness: 34 mm

- Minimum Sash Dimensions: 700 x 1200 mm

- Maximum Sash Dimensions: 1500 x 2000 mm

- Maximum Sash Weight: 155 kg

- EN 12152 Air Permeability: A4 – 600 Pa

- EN 12154 Water Tightness: RE 1200 Pa

- EN 13830 Wind Resistance: 1200 Pa

- Minimum Thermal Insulation: Uf: 3.45 W/(m².K)

What are the Features of Silicone Facade Glass?

The glasses used in silicone facade systems have special features to provide various functionalities such as energy efficiency and security as well as aesthetic appearance and structural performance. Here are the basic features of silicone facade glasses.

Silicone Facade Glass Features

- High Durability: Silicone facade systems often use tempered or laminated glass. These types of glass are significantly more resistant to impact than regular glass and shatter into less hazardous fragments when broken.

- Energy Efficiency: Low-emissivity (Low-E) glass enhances a building’s energy efficiency. By moderating the amount of heat that enters the interior, these glass panels help lower heating and cooling costs.

- Solar Control: Solar control glass filters sunlight to prevent excessive heat buildup and reduces the harmful effects of UV rays. This contributes to a more comfortable indoor environment.

- Sound Insulation: Laminated glass provides excellent sound insulation thanks to its special polyvinyl butyral (PVB) interlayer between two or more layers of glass.

- Safety and Security: Laminated glass holds together upon breaking, minimizing injury risks and offering an extra layer of protection against forced entry.

- Aesthetic Variety: Silicone facade glass is available in a wide range of colors and coatings, giving architects and designers more aesthetic choices.

- Thermal Insulation: The air or gas-filled spaces between multiple layers of glass significantly improve thermal insulation, reducing heat loss and enhancing energy efficiency.

- Eco-Friendliness: Energy-efficient glass helps lower carbon footprints and contributes to sustainable building solutions.

These features of silicone facade glass provide modern buildings with both aesthetic appeal and superior functionality. The appropriate choice of glass depends on the project’s overall requirements, geographic location, and architectural design.

What are the dimensions of silicone facade glass?

The glass used in silicone facade systems can be designed in different sizes, taking into account structural requirements, aesthetic expectations and functional needs. Here are some details about the typical sizes of silicone facade glass.

Silicone Facade Glass Dimensions

| Feature | Value |

| Glass Thickness | 20 mm – 34 mm |

| Minimum Wing Dimensions | 700 mm x 1200 mm |

| Maximum Wing Dimensions | 1500 mm x 2000 mm |

| Maximum Wing Weight | 155 kg |

These dimensions show the design and application flexibility of silicone facade systems and provide solutions that are suitable for the aesthetic and functional requirements of the project. However, it is important to make a detailed plan regarding glass dimensions and features, taking into account the unique requirements of each project.

What are the Colors of Silicone Facade Glass?

The glass used in silicone facade systems can be available in a variety of colors and coatings according to aesthetic and functional needs. The color of the glass is usually achieved by metal oxides added to the glass or by coatings applied to the glass surface. These colors and coatings are selected for solar control, thermal insulation, privacy and aesthetic preferences. Here are some of the colors commonly used in silicone facade glass.

Silicone Facade Glass Colors

- Transparent / Natural: Standard glass tint provides maximum transparency and natural light transmission.

- Bronze: Absorbs a portion of sunlight, offering a warmer appearance while helping to reduce overheating.

- Gray: A neutral color that provides solar control while maintaining visual comfort and balancing light transmittance.

- Blue: Blue shades offer an aesthetic appeal and are particularly chosen for structures near the sky or water. They also have light-filtering properties.

- Green: Provides a natural appearance and absorbs some sunlight, contributing to thermal insulation.

- Reflective / Mirror-Effect: Reflects sunlight and heat, helping to keep indoor spaces cool. Additionally, it creates a reflective surface from the outside, providing privacy.

- Opaque / Matte: Provides full opacity or translucency (semi-transparent), maintaining light transmission while offering privacy.

<p>Glass colors not only support the unique aesthetic appearance of the building design but also influence energy efficiency and indoor comfort. Therefore, selecting the glass color should be carefully considered based on the overall requirements, location, and orientation of the project.</p>

Silicone Facade Details

How to Make a Silicone Facade?

The manufacturing of silicone facade systems requires careful planning and implementation to create a modern facade solution that combines aesthetics and functionality. Here are the basic stages of this process.

Silicone Facade Production

- At the start of the project, a detailed design and engineering study is conducted, considering the facade’s aesthetic, structural, and energy efficiency requirements.

- The dimensions, thicknesses, colors of the glass, and the specifications of the aluminum profiles are determined.

- Aluminum profiles are cut to the specified dimensions and subjected to necessary processes (drilling, shaping, surface treatments, etc.).

- Glass panels are cut according to the project’s requirements.

- Additional processes such as tempering, lamination, and coating are applied to enhance the glass’s performance characteristics.

- Special strips are attached to the edges of the insulated glass units. These strips play a critical role during the installation process, serving as connection points for the clips that secure the glass panels to the aluminum support profiles.

- Opening sashes to be integrated into the façade are specially manufactured and prepared for installation in line with ventilation or access requirements.

- At every stage of the manufacturing process, quality control procedures are conducted to ensure the products meet design and engineering requirements.

- The completed façade elements are carefully packaged to prevent damage and prepared for delivery to the installation site.

These stages ensure the successful manufacturing of silicone facade systems and the subsequent high performance and aesthetic integrity during installation. Each step must be meticulously planned and implemented in accordance with the project requirements.

How to Install Silicone Facades?

Silicone Facade Installation

- The installation site is cleaned and prepared.

- Ensure all necessary materials and tools are available on site.

- Anchor connections are installed to the building’s main structural system. These connections ensure the aluminum support system is securely fixed to the structure.

- Aluminum support profiles are installed using anchor connections, and necessary alignments are performed.

- The support system is designed to bear the weight of the glass panels.

- Gaskets and seals are placed on and between the aluminum profiles to ensure water and air tightness.

- The glass panels are installed on the pre-prepared aluminum carrier system. The edge trim of the glass and special clips play a critical role at this stage.

- After the glass panel is positioned within the aluminum carrier system, clips are inserted into the edge trims (4–5 per side) and screwed into the aluminum carrier to complete the installation.

- Silicone is applied between the assembled glass panels to provide extra water and air tightness and to achieve an aesthetic appearance.

- Openable wings designed according to ventilation or access needs are integrated into the system.

- Once the installation is complete, a general check is conducted to ensure the facade is properly and securely mounted.

- Waterproofing tests and other necessary evaluations are performed to confirm the system’s performance.

These steps ensure the successful completion of the silicone facade installation. This process, which requires expertise and experience, guarantees the aesthetic appearance, structural integrity and long-term performance of the facade. It is important to pay attention to safety precautions and use appropriate tools during installation.

What are the Costs of Silicone Facades?

Silicone facade costs can vary greatly depending on a number of factors. These include the type of glass, the thickness of the glass, the size and quality of the aluminium profiles used, the overall design of the facade, the labour costs, the geographic location of the project and additional features (e.g. opening sashes, special cladding). Below is a guide to the main factors affecting silicone facade costs and the overall costs.

Silicone Facade Costs

- Material Costs:

- The type of glass (tempered, laminated, low-e coated, etc.) and its thickness significantly influence the overall cost.

- The quality and size of aluminum profiles have a direct impact on the total expense.

- Special coatings and insulation materials can add additional costs.

- Design and Engineering:

- Complex designs and unique engineering requirements may increase project expenses.

- Labor Costs:

- The complexity of installation and the required level of expertise influence labor costs. Additionally, labor rates vary depending on geographic location.

- Transportation and Logistics:

- The cost of transporting materials from the production site to the construction area can affect the overall budget.

- Additional Features and Functions:

- Extras like operable panels or automated ventilation systems can drive up costs.

Silicone Facade Prices

As of 2024, the average cost of silicone facade systems typically ranges between $180 and $220 per square meter. However, this is only a starting point, and specific project requirements may lead to higher or lower costs. For example, the use of high-performance energy-efficient glass, special design features, or challenging installation conditions can increase expenses.

For an accurate cost estimate, it’s essential to obtain detailed quotes from local suppliers or facade system specialists. These quotes will provide a more precise projection by considering materials, labor, design, and installation costs for the entire project.

Silicone Facade Companies

Silicone facade systems are an important exterior solution that brings together aesthetics and functionality in modern architectural projects. There are many companies that specialize in the design, manufacturing and installation of these systems. These companies offer innovative solutions to add value to buildings and increase energy efficiency by using high-quality materials and following the latest technology. In particular, companies such as Üçgen Alüminyum stand out in this field.

Üçgen Alüminyum:

- About: Üçgen Alüminyum is a company specializing in silicone facade systems. By offering innovative and customized solutions, it aims to meet both the aesthetic and functional needs of projects.

- Products and Services: Üçgen Alüminyum provides a broad range of services from the design, manufacturing, and installation of silicone facade systems. It also offers various product options, including energy-efficient glass, custom aluminum profiles, and multiple surface treatments.

- Quality and Reliability: Prioritizing customer satisfaction, the company delivers high-quality products and services. Üçgen Alüminyum has a solid track record of completing projects on time and within budget.

- Innovation: The company closely follows technological advancements in the industry and focuses on developing sustainable architectural solutions.

Other companies that provide services in the field of silicone facade systems are generally committed to providing customized solutions for customer needs and completing projects to the highest standards. However, companies that stand out in the sector, such as Üçgen Alüminyum, make a difference with their experience, innovative approaches and customer-focused service approach. Choosing the right company to meet the unique requirements of each project is one of the keys to a successful silicone facade system application.