What is a Cladding Facade?

Cladding facade systems are building elements that cover the exterior surfaces of structures, commonly used for purposes such as aesthetics, thermal insulation, and weather resistance. Glass curtain walls are among the most popular types of these facade cladding systems.

Glass curtain wall systems provide buildings with a modern appearance while allowing natural light to enter the interior. These glass facades can feature various design and structural characteristics. Glass curtain wall systems can enhance a building’s energy efficiency and offer sound insulation from external noise.

Cladding facade systems may incorporate not only glass but also aluminum and other materials.

Types of Curtain Wall Systems

Cladding walls can be classified in various ways according to the materials used, assembly methods and aesthetic structures.

They are facades made of aluminum composite panels or other composite materials. They are generally light and durable.

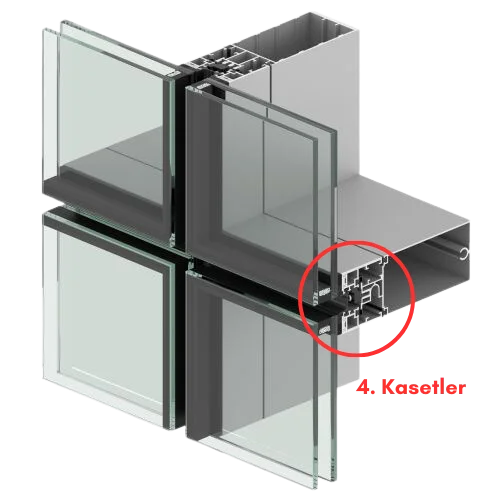

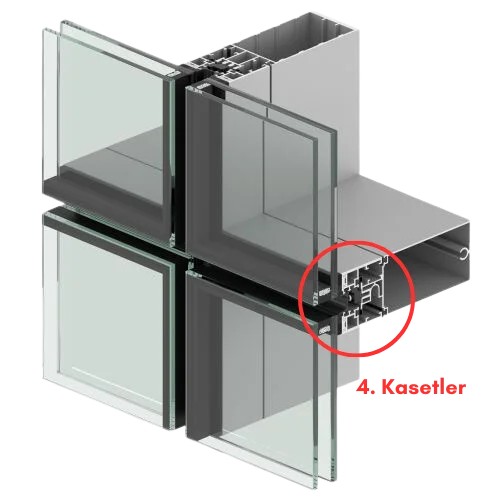

In this system, the glass is bonded to the cassette profiles with the help of structural silicones. This cassette system is mounted on the building frame. This system, which is preferred due to its ease of assembly and durability, is generally more costly.

The glass is mounted directly to the building frame with the help of special clips and glazing beads. This cassette-free system is a more economical and robust option, but the installation process is long.

In this system, the glasses are screwed to the carrier system with pressure profiles and covered with cover profiles. It provides a framed appearance when viewed from the outside.

It has the same logic as the capped curtain wall system, the only difference is that the cap profiles are only in one direction, for example only vertically or only horizontally.

In this façade, the glass panels are supported by special metal connections called “spiders”. This system creates a façade that is completely transparent and has few components when viewed from the outside.

These are facades created by mounting pre-manufactured panels or modules onto the building surface. They offer the advantage of quick assembly.

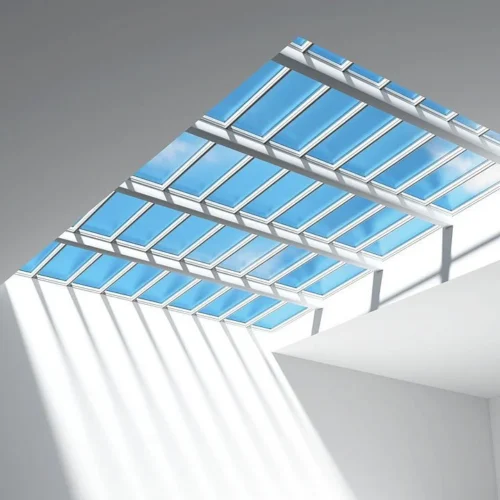

They are glass systems that are generally used on the roofs of buildings and allow natural light to come in. They are important in terms of both aesthetics and lighting.

These classifications demonstrate the wide variety of designs and functions available for curtain walls. The choice of facade can vary depending on the building’s location, climate conditions, aesthetic expectations, and budget.

Where Are Curtain Walls Used?

Curtain walls are an integral part of modern building design, offering numerous advantages such as aesthetics, energy efficiency, thermal insulation, and soundproofing. For these reasons, they are widely preferred across various building types.

Structural Silicone Curtain Wall Components

Curtain walls are frequently used in multi-storey office buildings located in city centres and business districts due to their aesthetic and energy efficiency advantages.

Large shopping malls can maximize natural light intake thanks to glass curtain walls.

In hotels, curtain walls are preferred to provide a modern look and a comfortable indoor climate.

Curtain walls are frequently used in hospitals for reasons such as energy efficiency, hygiene and natural light intake.

Universities, colleges and schools can use curtain walls to provide students and staff with a more comfortable learning and working environment with modern and impressive architecture.

In large terminal buildings, curtain walls are used to provide passengers with a spacious waiting area while also improving energy efficiency.

In sports facilities such as stadiums, gyms and swimming pools, curtain walls are used to increase natural light intake and save energy.

In some industrial facilities, curtain walls can be used to provide natural light intake and energy efficiency.

Curtain walls can be preferred in places such as museums, theaters and concert halls to combine aesthetics and functionality.

Curtain walls, as part of modern architectural design, offer many advantages such as aesthetics, energy efficiency, thermal and sound insulation. For these reasons, they are preferred in many different types of buildings.

Why Are Cladding Wall Systems Preferred?

Curtain wall systems are widely preferred in the modern construction industry due to their aesthetic and functional advantages. Here are the features and benefits of curtain wall systems:

Curtain Wall System Features

- Modular Structure: Curtain walls generally consist of pre-fabricated modules, speeding up the installation process.

- Lightweight Structure: Made from aluminum, glass, and other lightweight materials, they reduce the load on the building.

- Flexible Design: With a variety of colors, textures, and material options, they offer great flexibility for architectural design.

- Transparency: Especially with glass curtain walls, they allow natural light to penetrate indoors.

Curtain Wall System Advantages

- Modern Aesthetic: Curtain walls offer a contemporary and impressive architectural appearance.

- Energy Efficiency: They provide thermal insulation, reducing energy costs. Double glazing or special coatings prevent excessive solar heat gain.

- Natural Light: Glazed curtain walls let in abundant natural light, improving energy efficiency and interior quality.

- Acoustic Insulation: They provide soundproofing against exterior noise, enhancing indoor quietness.

- Weatherproofing: Curtain walls improve indoor comfort by preventing water leaks and air drafts.

- Durability: With proper materials and installation, curtain walls remain robust for many years.

- Easy Maintenance: They resist dirt, dust, and external wear, making them simple to clean and maintain.

- Building Protection: Curtain walls safeguard the structure against external elements, particularly harsh weather conditions.

What Are the Curtain Wall Materials?

Materials used in curtain wall systems vary depending on aesthetic, functional, cost, and durability requirements.

What are the Curtain Wall Components?

Curtain wall systems consist of many different components that work together to ensure the functionality, durability and aesthetics of the facade.

Curtain Wall Components:

Curtain walls serve as the main structural support component. They are typically made from aluminum. These profiles are mounted on the building’s exterior surface and carry other facade elements.

a) Curtain Wall Profile Dimensions: The dimensions of these profiles vary depending on project requirements, building height, wind loads, and the size of the glass or panels to be used. Generally, these profiles are custom-designed and produced according to the project’s needs. The dimensions are determined based on both aesthetic and functional factors.

b) Material: They are usually made of aluminum, but steel or other metals can also be used.

c) Function: These profiles are mounted on the building’s exterior surface and support other facade elements. They are also crucial for water and air tightness, as well as thermal insulation.

These are the glass panels used in curtain walls. They form the largest and most significant part of the exterior appearance.

a) Curtain Wall Glass Dimensions: The dimensions of the glass panels used in curtain walls vary from project to project. Generally, the size of the glass panels is determined by factors such as building height, wind loads, aesthetic considerations, and installation requirements.

b) Curtain Wall Glass Thickness: The thickness of the glass is usually determined by the building’s height, wind loads, and thermal performance requirements. In double or triple glazing systems, the glass layers are separated by an air gap, enhancing insulation performance.

c) Curtain Wall Glass Colors: Glass can come in its natural color or be produced in various colors to meet energy efficiency or aesthetic objectives. Commonly preferred colors include bronze, green, blue, and gray.

d) Curtain Wall Glass Properties: Glass panels can be enhanced with special coatings or treatments to provide features such as UV protection, solar control, low-emissivity coatings (for thermal insulation), and safety or laminated properties.

- Exterior cladding panels made from aluminum composite, metal, stone, or other materials.

- Structural components used for attaching glass panels or other cladding materials to the supporting profiles.

- Provides water and air tightness at the joints of glass or panels.

- While providing an aesthetic appearance, it also covers mechanical fasteners and other assembly details.

- It allows the carrier profiles to be mounted on the exterior surface of the building.

- Screws, bolts, steel dowels and other assembly elements are used to assemble the curtain wall elements.

- Sunshades, blinds or other shading systems can increase indoor comfort by reducing the direct effects of the sun.

These elements are the fundamental components of curtain wall systems. However, depending on the specific facade design and materials used, additional elements or features may be added to this list. The assembly and design of curtain walls, combined with the correct selection of materials and components, result in a long-lasting, durable, and aesthetically pleasing structure.

How Are Curtain Walls Made?

The manufacturing and installation of curtain walls involve a complex process with several stages. This process includes design, manufacturing, and assembly phases.

Curtain Wall Manufacturing and Assembly:

- Design and Planning: At this stage, the aesthetic, functional, and structural requirements of the facade are determined. Factors such as building height, wind load, climatic conditions, and energy efficiency are carefully considered.

- Material Selection: Materials such as glass, aluminum, stone, or metal panels are chosen based on project requirements and budget.

- Detailed Drawings: Detailed specifications for the manufacturing and installation of each component are prepared.

- Curtain Wall Manufacturing:

- Profile Manufacturing: Aluminum profiles are cut and processed according to specified dimensions and shapes.

- Glass Manufacturing: Glass panels are cut, processed, and, if necessary, coated with specialized finishes based on the chosen type and characteristics.

- Panel Manufacturing: Composite, stone, or metal panels, if required for the project, are fabricated to the specified dimensions.

- Assembly Preparation: The fabricated components are transported to the site along with the necessary mounting apparatus, screws, and other fastening elements.

- On-Site Assembly:

- Installation of Supporting Framework: The aluminum structural profiles are first attached to the building’s exterior. This serves as the primary support system for the curtain wall.

- Glass and Panel Installation: Subsequently, glass panels or other cladding materials are mounted onto the structural profiles.

- Sealing and Insulation: Sealing materials such as silicone, gaskets, and other insulating components are used to ensure air and water tightness.

- Completion and Inspection: Once assembly is complete, all connections are inspected, any deficiencies or errors are corrected, and final checks are conducted.

The manufacturing and assembly of curtain walls require expertise and are typically carried out by a team of experienced engineers, architects, and skilled craftsmen.

Curtain Wall Companies

Companies specializing in curtain walls design, produce, and install exterior cladding solutions to enhance the aesthetics, functionality, and energy efficiency of buildings. These companies often provide services ranging from design and engineering to manufacturing and assembly. Due to the importance of curtain walls in modern building design, the number and expertise of such companies are increasing steadily.

Many curtain wall companies operate on a global scale, while others focus on local or regional markets. Companies typically offer customized solutions tailored to the project’s characteristics, budget, and requirements.

Üçgen Alüminyum is one of the firms operating in the curtain wall sector. The company specializes in the production of aluminum-based curtain wall systems. By offering tailored aluminum profiles, cladding materials, and installation solutions for various projects, Üçgen Alüminyum has increased its recognition in the industry. The products and services offered by Üçgen Alüminyum are of high quality, durability, and aesthetic standards, and have been featured in many successful projects.

In general, when choosing a company that specializes in curtain walls, it’s important to consider their experience, previous project successes, material quality, and engineering capabilities. This ensures the project is both aesthetically and functionally successful.

Curtain Wall Prices

Curtain wall costs can vary depending on numerous factors. Below are the key factors influencing curtain wall prices:

Curtain Wall Prices

- Material Type: The type of materials used (glass, aluminum, stone, composite panels, etc.) directly affects costs. For example, high-quality low-e glass or specially treated metal claddings are more expensive than standard materials.

- Design Complexity: Custom designs or complex structural features can increase costs.

- Building Height: Taller buildings may require more robust materials and systems due to wind loads and other structural demands, impacting costs.

- Technological Features: Features such as energy efficiency, automated shading devices, or smart glass technologies can drive up costs.

- Manufacturing and Installation Process: The complexity of the installation, special equipment, or skill requirements can affect costs.

- Transport and Logistics: Material transportation costs for the project can influence the overall budget.

- Regional Factors: Prices may vary based on local economic conditions, labor costs, and material availability.

- Additional Features: Features such as fire resistance, sound insulation, or special sealing requirements can increase costs.

How much do curtain wall systems cost?

It is challenging to provide a definitive answer to this question since prices can vary significantly depending on the factors mentioned above. However, to create an accurate budget for a specific project, obtaining quotes from curtain wall companies is advisable. For project assistance, please contact us.

Curtain Wall Static Calculations

Static calculations for curtain walls ensure that the facade components forming the building’s outer shell are safely designed and implemented against various loads and effects. These calculations guarantee that the curtain wall remains durable under natural forces and provides structural integrity for both the support structure and the facade.

Key considerations in curtain wall static calculations:

- Wind Load: Building exteriors are subjected to wind forces, making wind load resistance critical. Wind speed, direction, and building height are all factored into these calculations.

- Self-Weight: The self-weight of the curtain wall impacts both the facade components and the supporting structure, so it must be carefully accounted for.

- Seismic Load: Turkey is located in an active seismic zone. The major earthquakes such as the 2023 Hatay Earthquake have underscored the importance of designing structures, including curtain walls, in accordance with seismic regulations. Curtain walls should be specifically designed to withstand seismic forces without causing harm to the building or surrounding area. Static calculations are essential to ensure the facade does not detach or collapse during seismic activity.

- Thermal Movements: Material expansion or contraction due to temperature changes can impact the structural integrity of the facade. Therefore, static calculations must address thermal movements to develop a resilient design.

- Other Loads: Snow loads, maintenance-related loads, and other external factors are also considered in static calculations.

Considering the frequency and severity of earthquakes in Turkey, it is crucial to factor in seismic loads when designing and implementing curtain wall systems. Curtain wall static calculations must comply with Turkish seismic codes and standards. For project-specific static calculations, please contact us.

Are Curtain Wall Materials Fire-Resistant?

The fire resistance of curtain wall materials depends on the type, quality, and manufacturing technology of the materials used. Generally, curtain wall materials must meet certain fire resistance standards, especially for high-rise buildings or densely occupied areas. Below is some information about the fire resistance of different curtain wall materials.

Curtain Wall Fire Resistance

- Glass: Glass alone begins to melt at high temperatures. However, there are fire-resistant glass types designed to prevent the spread of flames and smoke during a fire. These types of glass are recommended as part of a fire protection strategy, especially in high-rise buildings.

- Aluminum: Aluminum’s melting point makes it susceptible to deformation in most fire conditions. However, aluminum profiles are often insulated with fire-retardant materials. This insulation can help prevent aluminum from overheating and melting during a fire.

- Composite Panels: These panels consist of a metal outer layer and a core made of various materials. Depending on the core material (e.g., polyethylene or mineral wool), the fire performance of composite panels can vary significantly. While some composite panels ignite easily, others are fire-resistant.

- Stone and Ceramic Claddings: These materials are typically highly fire-resistant. They do not ignite and retain their protective properties even under high temperatures.

- Wood and Timber Claddings: These materials are naturally combustible, but fire-protected treated timber claddings are also available.

A building’s fire safety relies not only on its exterior materials but also on its overall design, fire alarm systems, suppression systems, and other safety measures. For new building projects, choosing materials that comply with fire regulations is essential. Local and national fire codes specify fire resistance requirements, and curtain wall materials must adhere to these standards.

How to Clean Curtain Walls?

The cleaning of curtain walls is important for maintaining the aesthetic and functional features of a building’s exterior. However, properly cleaning a curtain wall requires attention to detail and depends on the type of material and the specific characteristics of the facade.

Curtain Wall Cleaning

- Preparation Stage:

- Before cleaning, refer to the manufacturer’s cleaning instructions for the curtain wall material.

- Protect any fixtures on the facade (such as lighting fixtures or cameras).

- Ensure appropriate safety measures are in place when cleaning tall buildings. Professional equipment and trained personnel are recommended for exterior cleaning.

- Cleaning Materials and Solutions:

- Use a soft sponge, microfiber cloth, or soft brush to gently clean the surface.

- Avoid harsh chemicals or abrasive materials that can damage the surface. Instead, use a mild detergent with a neutral pH and warm water solution.

- For glass surfaces, rinse with clean water to prevent mineral deposits and stains.

- Cleaning Method:

- Clean the surface from the bottom up to avoid water and detergent residue on lower sections.

- Use a squeegee for glass curtain walls to remove trapped dirt effectively.

- For stains and dirt, apply a mild detergent solution and rinse thoroughly with water.

- Drying:

- Dry the surface quickly to prevent water spots. This can be done using microfiber cloths or squeegees.

- Periodic Cleaning:

- The frequency of cleaning depends on the region’s climate, air pollution, and other external factors. Generally, it is recommended to clean the facade at least once or twice a year.